Critical to maintaining a reliable backup battery solution, a battery monitoring system will provide users with the data they need to proactively service or replace a failing battery by measuring key parameters in real-time. Eagle Eye Power Solution’s Battery Monitoring Division offers products that identify and measure key parameters as outlined in IEEE and NERC compliance recommendation for lead acid battery monitoring systems:

- String voltage

- Float current

- Cell voltage

- Cell resistance

- Connection & terminal resistance

- Negative post temperature

- Ground fault

- Ambient temperature

- Optional: Electrolyte level

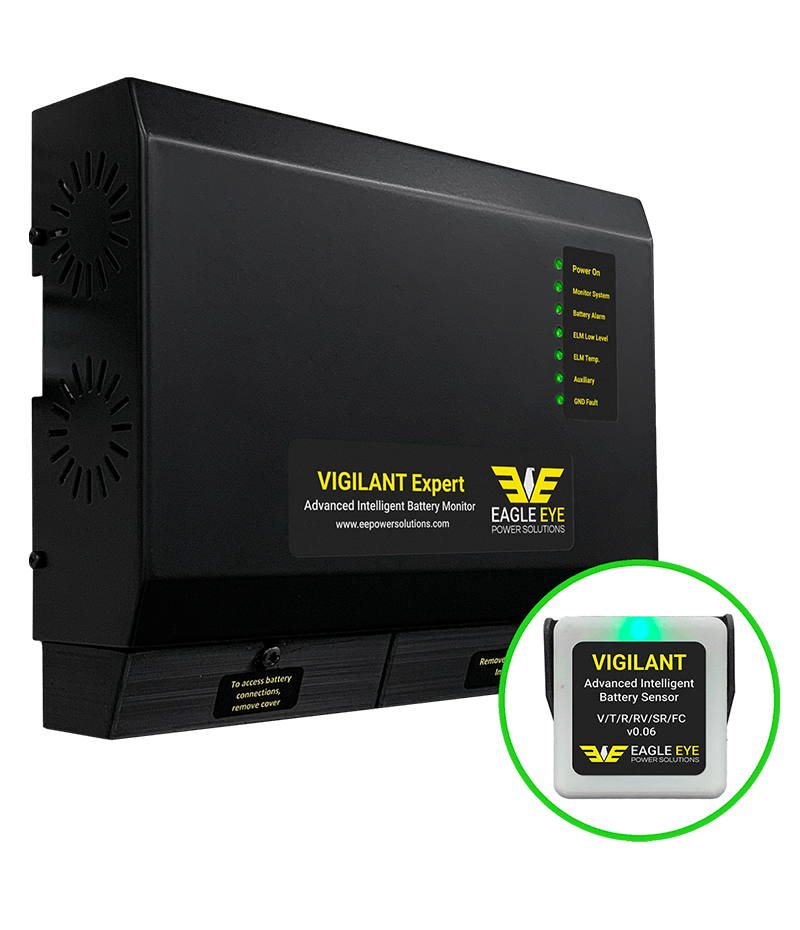

Learn more about how VIGILANT™ and other cutting-edge Eagle Eye Power Solutions battery monitoring systems can help you Increase Reliability, Decrease Costs, & Meet Compliance.

BQMS Battery Health Monitoring System

Battery Monitoring Solutions for Utility, Telecom, Data Center and UPS

Want to try it out?

See why investing in a pilot BMS system is an essential investment when considering your battery monitoring options.

Get a Quote >