Battery Monitoring for NERC Compliance

The VIGILANT™-NERC system is Eagle Eye Power Solutions’ complete battery monitoring solution for NERC PRC-005-6 Compliance. This standard requires utilities to document and implement programs for the maintenance of all protection systems affecting the reliability of the bulk electric system (BES).

Under NERC PRC-005-6, battery maintenance falls under Table 1-4(f) “Exclusions for Protection System Station DC Supply Monitoring Devices and Systems” with no maximum maintenance interval. This table outlines the monitoring and alarming requirements needed to alleviate periodic on-site maintenance activities.

Monitoring for NERC Compliance

The attributes in Table 1-4(f) call out monitoring and alarming of the key battery parameters listed below. The VIGILANT complies in monitoring all of these parameters:

- String Voltage: Provides high and low monitoring and alarming of string voltage at the battery positive & negative terminals.

- Electrolyte Level: Provides alarming and identification of low electrolyte level for every cell with infrared ELM sensors.

- Ground Fault: Provides monitoring and alarming for unintentional DC ground fault by measuring earth potential relative to battery voltage.

- Float Voltage: Provides monitoring and alarming of float voltage at the battery positive & negative terminals to ensure correct float voltage is being applied.

- String Continuity: Monitors the precise float current in the battery by accurately measuring the potential difference across the cell interconnections, enabling reliable detection if the battery has a continuity fault.

- Intercell and Terminal Connection Resistance: Provides monitoring and alarming of battery terminal resistance and each intercell connection resistance as independent values.

- Internal Ohmic Value & Float Current: Provides monitoring and alarming of each cell’s internal resistance against an established baseline.

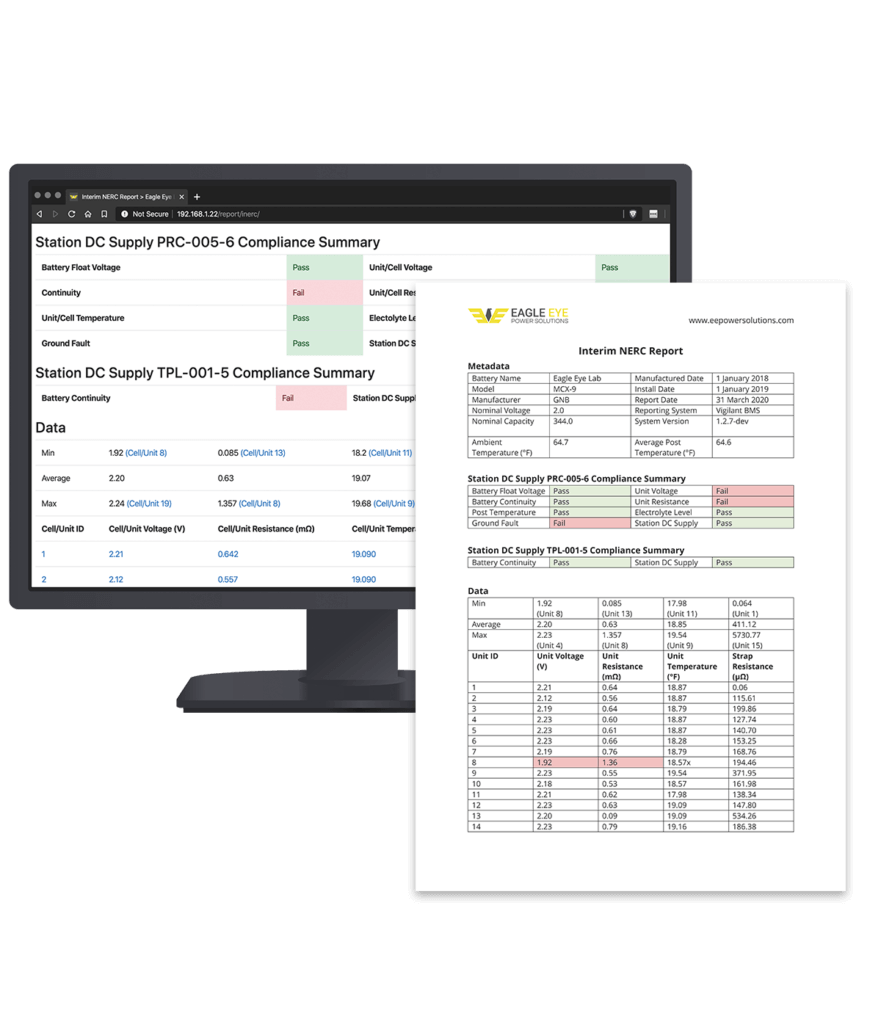

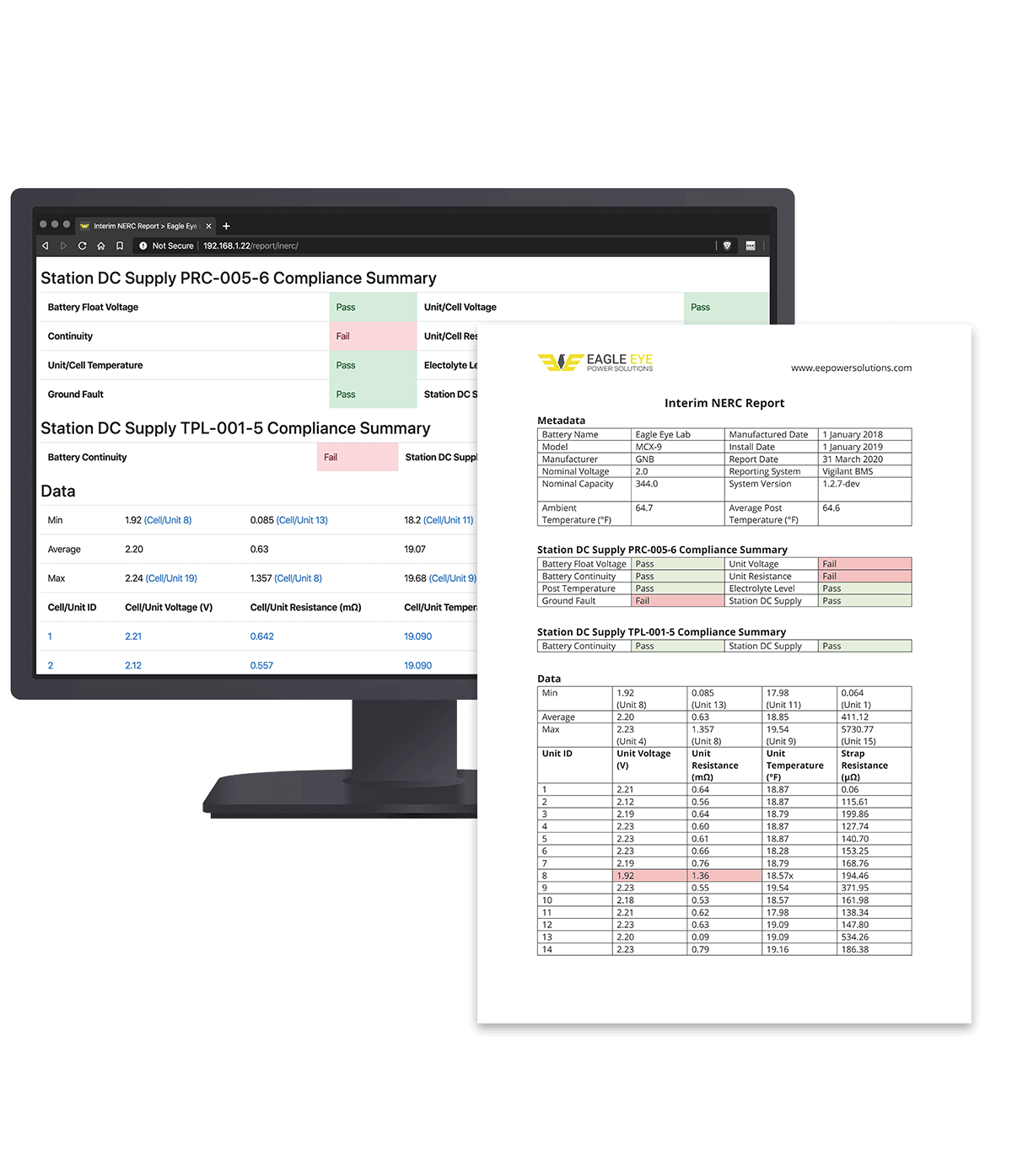

Reporting for NERC

The key element to meeting NERC compliance for battery monitoring is have access to detailed reports that prove compliance to the standard. The VIGILANT provides one-click NERC reporting to make this step as easy as possible and remove the guesswork of what needs to be included. Using the built-in web-server, the VIGILANT can generate a detailed PDF report.

VIGILANT Table of Compliance – NERC PRC-005-6: Table 1-4(f)

| Clause | Title | Status | Comment |

|---|---|---|---|

| Table 1-4(f) | Any station DC supply with high and low voltage monitoring and alarming of the battery charger voltage to detect charger overvoltage and charger failure (See Table 2). | Complies | VIGILANT monitors and alarms for float voltage from the charger, measured at the charger cables. |

| Table 1-4(f) | Any battery based station DC supply with electrolyte level monitoring and alarming in every cell (See Table 2). | Complies | VIGILANT monitors and alarms for electrolyte level of every cell with the ELM sensor. |

| Table 1-4(f) | Any station DC supply with unintentional DC ground monitoring and alarming (See Table 2). | Complies | VIGILANT monitors the voltage to ground balance and alarms on fault detection. |

| Table 1-4(f) | Any station DC supply with charger float voltage monitoring and alarming to ensure correct float voltage is being applied on the station DC supply (See Table 2). | Complies | VIGILANT monitors and alarms for float voltage from the charger, measured at the charger cables. |

| Table 1-4(f) | Any battery based station DC supply with monitoring and alarming of battery string continuity (See Table 2). | Complies | VIGILANT monitors the internal resistance and float current of each cell, which will create a continuity specific alarm if a break in string continuity is detected. |

| Table 1-4(f) | Any battery based station DC supply with monitoring and alarming of the intercell and/or terminal connection detail resistance of the entire battery (See Table 2). | Complies | VIGILANT monitors terminal resistance between battery posts and charger cables and inter-cell connections between each cell in microohms. |

| Table 1-4(f) | Any Valve Regulated Lead-Acid (VRLA) or Vented Lead- Acid (VLA) station battery with internal ohmic value or float current monitoring and alarming, and evaluating present values relative to baseline internal ohmic values for every cell/unit (See Table 2). | Complies | VIGILANT monitors and alarms for internal ohmic value against a calculated baseline using warning and critical limits. Float current is also measured. |

| Table 1-4(f) | Any Valve Regulated Lead-Acid (VRLA) or Vented Lead- Acid (VLA) station battery with monitoring and alarming of each cell/unit internal ohmic value (See Table 2). | Complies | VIGILANT monitors and alarms for each cell/unit internal ohmic value in milliohms. |

VIGILANT Table of Compliance – NERC TPL-001-5, Table 1, Footnote 13c

| Clause | Title | Status | Comment |

|---|---|---|---|

| Table 1, 13c | A single station DC supply associated with protective functions required for Normal Clearing (an exception is a single station DC supply that is both monitored and reported at a Control Center for both low voltage and open circuit); | Complies | The VIGILANT system monitors battery continuity and station DC supply. Should these parameters raise an alarm, the system will alarm via general alarm relay and/or Modbus alarm point. |

Visit Eagle Eye University for information on our battery training courses.