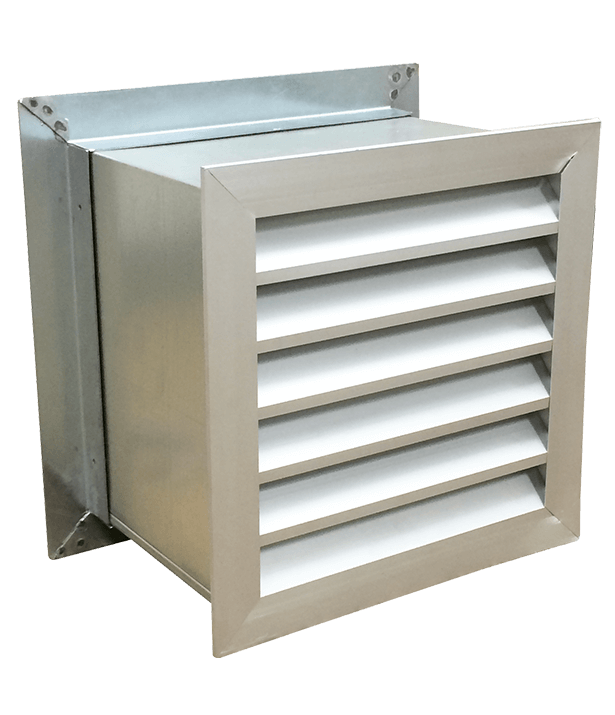

VS-12 Battery Exhaust Fan

The VS-12 battery exhaust fan is a 850 CFM forced fan system used in battery charging rooms and other locations where motive power and stationary batteries are present. The VS-12 can also be used where there is a possibility of other flammable or toxic gasses accumulating in a confined spaced. It is designed to be used in conjunction with the Eagle Eye Power Solutions HGD-3000 gas / smoke detector with silent intrusion alarm. The VS-12 combined with the HGD-3000 provides an all in one package ideal for remote and other locations requiring a low-cost, easy to install system.

Benefits

- Compliant with NEC 501, Class I Division II Group B

- 850 CFM wall mounted fan

- Powered dampers

- Designed for use with explosive or toxic gas detectors, including the Eagle Eye Power Solutions HGD-Series

- LED status display

- Motorized dampers locked when open or closed

- Simple installation with sliding collar to fit different wall thicknesses

- Long operating life

- Available in 120 VAC and 24 or 48 VDC versions

- 20-gauge galvanized steel

- Insurance premium reduction may be realized

Own a device that needs service or annual calibration?

Submit an RMA >Visit Eagle Eye University for information on our battery training courses.